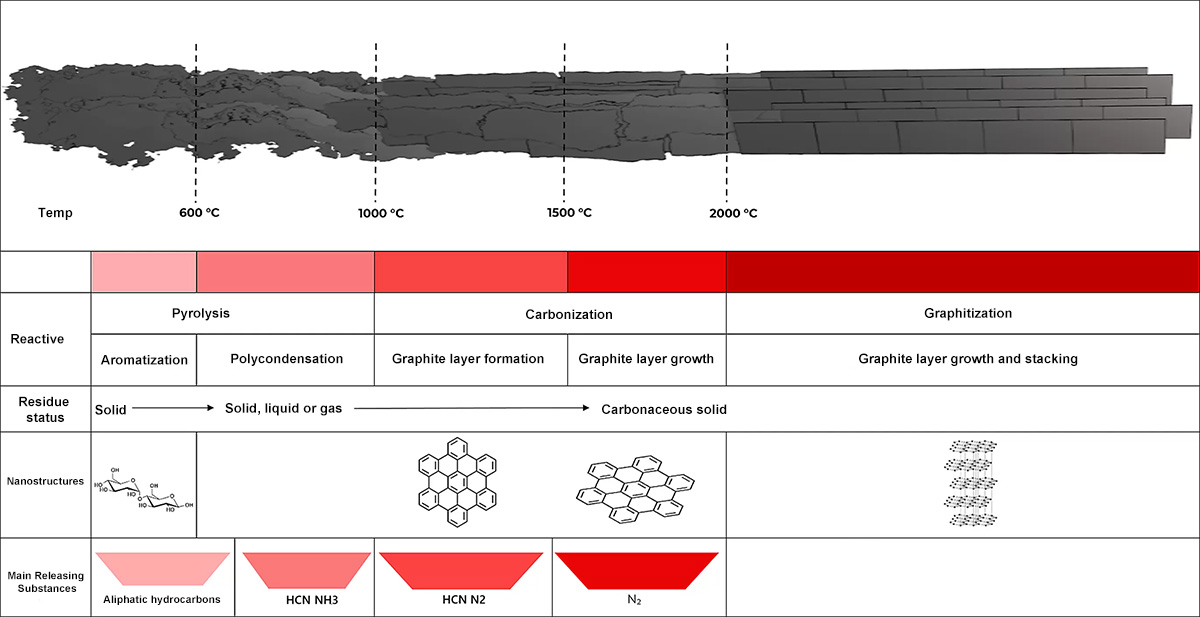

Fiilooyinka ceeriin ee ku salaysan PAN-ka waa in horay loo oksaydheeyay, heerkul hoose lagu shubay kaarboon, heerkul sarena lagu shubay kaarboon si loo sameeyo.Faybarro kaarboon ah, ka dibna la sawiray si loo sameeyo fiilooyinka garaafitka. Heerkulku wuxuu gaaraa 200℃ ilaa 2000-3000℃, kaas oo fuliya falgallo kala duwan oo sameeya qaabab kala duwan, kuwaas oo iyaguna leh astaamo kala duwan.

1. Marxaladda Pyrolysis:Ka-hor-oxidation qaybta heerkulka hooseeya, kaarboonaynta heerkulka hooseeya qaybta heerkulka sare

Kala-soocidda kahor-oksaydhku waxay dhacdaa, dhererka ku dhawaad 100 daqiiqo, heerkulka 200-300 ℃, ujeedadu waa in silsiladda macromolecular-ka toosan ee PAN loo beddelo qaab-dhismeedka trapezoidal ee aan balaastikada ahayn ee u adkaysta kulaylka, falcelinta ugu weyn ee silsiladda macromolecular ee wareegga iyo isku-xidhka intermolecular, oo ay weheliso falgalka pyrolysis iyo sii deynta molecules yar yar. Tusmada arylation guud ahaan waa 40-60%.

Heerkulka kaarboonaynta heerkulka hooseeyaGuud ahaan waa 300-800 ℃, inta badan falgalka dillaaca kulaylka, inta badan iyadoo la adeegsanayo kuleyliyaha foornada korontada ku shaqeeya ee heerkulka sare leh, marxaladdu waxay soo saartaa xaddi badan oo gaas qiiqa iyo daamur ah.

Astaamaha: Midabka faybarka horay loo oksaydhiyay wuxuu noqon doonaa mid madow, badanaa madow, laakiin wali wuxuu hayaa qaab-dhismeedka faybarka, qaab-dhismeedka gudaha wuxuu maray heer gaar ah oo isbeddello kiimiko ah, sameynta kooxo shaqeynaya oo ka kooban ogsijiin iyo qaab-dhismeed isku xiran, taasoo aasaaska u dhigaysa kaarboonaynta xigta.

2. Marxaladda kaarboonaynta (heerkulka sare), waa oksaydhaynta hore ee hordhaca ah ee jawi aan firfircoonayn marka heerkulku sarreeyo, ka saarista taas oo marka lagu daro heteroatomada kaarboonka (sida oksijiinta, haydarojiinta, nitrojiinta, iwm.), si loo helo kaarboonaynta tartiib tartiib ah, sameynta qaab-dhismeedka kaarboonka aan qaab-dhismeedka lahayn ama microcrystalline. Habkani waa tallaabo muhiim ah oo ku saabsan sameynta qalfoofka kaarboonka. Heerkulku guud ahaan wuxuu u dhexeeyaa 1000-1800 ℃, inta badan falcelinta uumiga kulaylka, inta badan kuleyliyeyaasha garaafka waxaa loo isticmaalaa kuleylinta.

Astaamaha: Qaybta ugu weyn ee walaxda kaarboonaysan waa kaarboon, qaab-dhismeedku inta badan waa kaarboon aan qaab-dhismeed lahayn ama qaab-dhismeedka garaafka fowdada ah, qaab-dhismeedka korantada, sifooyinka farsamada marka la barbar dhigo badeecada ka hor oksaydhka ayaa leh koror weyn.

3. Garaafayntawaa daaweyn kuleyl dheeraad ah oo lagu sameeyo alaabada kaarboonaynta heerkulka sare si kor loogu qaado qaab-dhismeedka kaarboon aan qaab-dhismeed lahayn ama kaarboon microcrystalline ah si loo helo qaab-dhismeed kiristaal graphite ah oo nidaamsan. Iyada oo loo marayo ficilka heerkulka sare, atamka kaarboonka ayaa dib loo habeeyaa si loo sameeyo qaab-dhismeed lakab shabag ah oo lix geesle ah oo leh heer sare oo jiho ah, sidaas darteed si weyn ayaa loo hagaajiyaa korantada iyo kulaylka iyo xoogga farsamada ee walaxda.

Astaamaha: Badeecada garaafka leh waxay leedahay qaab-dhismeed garaafit aad u fiican, kaas oo bixiya koronto iyo kuleyl aad u fiican, iyo sidoo kale xoog gaar ah oo sare iyo modulus gaar ah. Tusaale ahaan, modulus sareFaybarro kaarboon ahwaxaa laga helaa heer sare oo garaafis ah.

Tallaabooyin gaar ah iyo shuruudaha qalabka ee kahor oksaydheynta, kaarboonaynta iyo garaafitaynta:

Kahor oksaydhaynta: waxaa lagu sameeyaa hawada heerkul la xakameeyey oo ah 200-300°C. Xiisadda ayaa loo baahan yahay in la mariyo si loo yareeyo yaraanta faybarka.

Kaarboonaynta: waxaa lagu sameeyaa jawi aan firfircoonayn iyadoo heerkulku si tartiib tartiib ah u kordho ilaa 1000-2000°C.

Graphitization: waxaa lagu sameeyaa heerkul sare (2000-3000°C), badanaa meel faaruq ah ama jawi aan firfircoonayn.

Waqtiga boostada: Maajo-22-2025