(1) Badeecadaha walxaha shaqeeya ee kulka dahaadha

Hababka habka dhaqameed ee ugu muhiimsan ee loogu talagalay hawo-qaadashada waxqabadka sare leh ee qaab-dhismeedka isku dhafanwalxaha kulka dahaadhawaa RTM (Maareynta Wareejinta Resin), qaabaynta, iyo layup, iwm. Mashruucani wuxuu qaadanayaa hab cusub oo wax lagu dhejiyo oo badan.

Habaynta RTM:

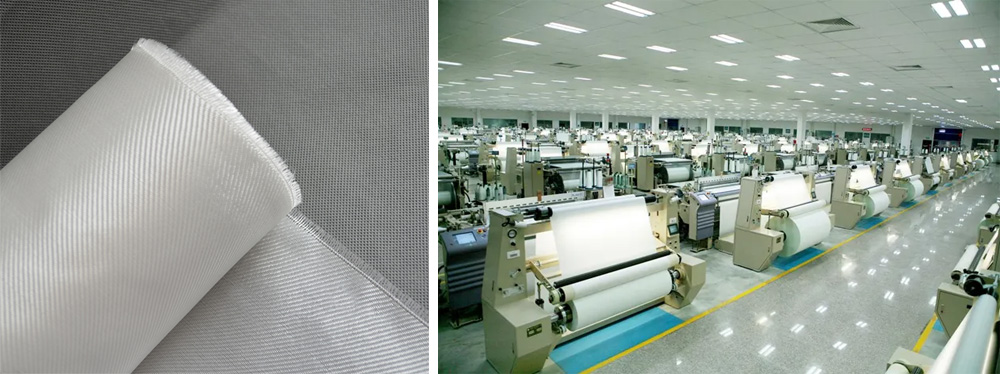

① Dhigista maro faybar ah: maro faybar quartz ah oo la diyaariyey ayaa hal mar la geliyaa godka caaryada;

② Cirbadda Resin-ka: resin-ka iyo kiciyeyaasha waxaa lagu qasaa isku-darka taagan ee ku yaal hore ee qoriga duritaanka waxaana lagu duraa godka caaryada oo lagu daboolay maro faybar ah.

③ Daaweynta Resin: godka caaryada ayaa la kululeeyaa si loo dedejiyo daaweynta resin-ka;

(iv) Burburinta Badeecada: Ka dib marka resin-ka la bogsado oo la qaabeeyo, caaryada ayaa la furaa si loo helo qaybta ugu dambeysa ee isku-dhafka ah.

Ka dib habka RTM (Resin Transfer Molding), maro faybar ah oo quartz ah ayaa la farsameeyaa oo lagu dhejiyaa qolofka birta ah, badeecada ka dib marka la sameeyona waa la qiimeeyaa ka dib tijaabada waxqabadka, taas oo ah badeecada la dhammeeyey.

(2) Agab isku-dhafan oo hirar-daahfuran ah

Faybar quartz ah oo la xoojiyayIsku-dhafka hirarka-daahfuran ee dhoobada ah oo ay diyaarisay habka dildilaaca ee lagu shubo precursor-ka organic precursor (PIP). Habka PIP waa in la isticmaalo preforms-ka fiber-ka ee la shubay ee organic precursor-ka ah, ka dibna pyrolysis, soo saarista matrix-ka fiber-ka quartz ee lagu shubo meelaha banaan ee preform-ka ah ee ku yaal billet-ka, ee billet-ka ka dib daaweynta rinjiyeynta buufinta si loo kormeero, loo kormeero iyo u-qalmitaanka kaas oo ah badeecada la dhammeeyay. Si loo hubiyo in dusha sare ee maaddada heerkulka cufnaanta loo baahan yahay ay aad uga hooseyso habka sintering-ka kulul ee cadaadiska, waxay yareyn kartaa dhaawaca fiilooyinka quartz-ka, waxayna leedahay astaamaha qaabaynta shabakadda, gaar ahaan ku habboon diyaarinta qaybaha walxaha mowjadaha-daahfuran ee cabbirka weyn.

(3) Agab gaar ah oo dahaarka lagu dahaadho

Themaro faybar quartz ahWaxaa lagu diyaarin doonaa godka caaryada, resin-ka waxaa lagu duri doonaa godka caaryada si uu uga buuxo godka caaryada maro faybar ah, iyadoo la kululeynayo godka caaryada si loo dedejiyo daaweynta resin-ka, loo sameeyo qaabaynta daaweynta resin-ka, loo furo caaryada loona helo agabka ugu dambeeya ee dahaarka leh.

Waqtiga boostada: Noofambar-11-2024