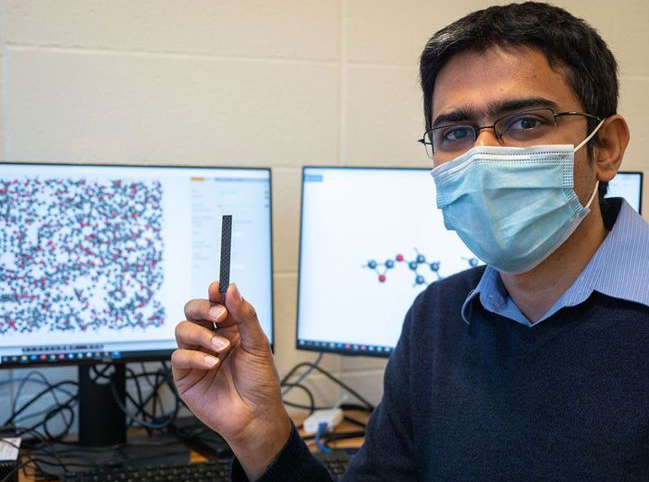

Dhowr maalmood ka hor, bare sare oo ka tirsan Jaamacadda Washington, Aniruddh Vashisth, ayaa daabacay warqad uu ku qoray joornaalka caalamiga ah ee Carbon, isagoo sheegay inuu si guul leh u sameeyay nooc cusub oo ah walxo isku dhafan oo kaarboon fiber ah. Si ka duwan CFRP-ga dhaqameed, kaas oo aan la hagaajin karin marka uu dhaawacmo, agab cusub ayaa si isdaba joog ah loo hagaajin karaa.

Iyadoo la ilaalinayo sifooyinka farsamada ee agabka dhaqameed, CFRP-ga cusub wuxuu ku darayaa faa'iido cusub, taas oo ah, waxaa si isdaba joog ah loo hagaajin karaa iyadoo la adeegsanayo kulaylka. Kulaylku wuxuu hagaajin karaa wixii dhaawac daal ah ee ku yimaada agabka, waxaana sidoo kale loo isticmaali karaa in lagu burburiyo agabka marka loo baahdo in dib loo warshadeeyo dhammaadka wareegga adeegga. Maadaama CFRP-ga dhaqameed aan dib loo warshadayn karin, waa muhiim in la sameeyo agab cusub oo dib loo warshadayn karo ama lagu hagaajin karo iyadoo la adeegsanayo tamarta kulaylka ama kuleylka raadiyaha.

Professor Vashisth wuxuu sheegay in isha kulaylku ay si aan xad lahayn dib ugu dhigi karto habka gabowga ee CFRP-ga cusub. Si adag marka loo hadlo, walaxdan waa in loogu yeeraa Carbon Fiber Reinforced Vitrimers (vCFRP, Carbon Fiber Reinforced Vitrimers). Polymer galaas (Vitrimers) waa nooc cusub oo walxo polymer ah oo isku daraya faa'iidooyinka balaastikada thermoplastic iyo thermosetting balaastikada oo uu ikhtiraacay saynisyahan Faransiis ah Professor Ludwik Leibler sanadkii 2011. Walaxda Vitrimers waxay isticmaashaa habka isdhaafsiga curaarta firfircoon, kaas oo samayn kara isdhaafsiga curaarta kiimikada ee la celin karo si firfircoon marka la kululeeyo, isla markaana ilaalin kara qaab-dhismeed isku xiran oo dhan, si polymers-ka thermosetting ay iskood isu bogsiin karaan oo dib loogu farsamayn karo sida polymers-ka thermoplastic.

Taas bedelkeeda, walxaha isku-dhafka ah ee loo yaqaan 'carbon fiber composite agabyada' waa walxaha isku-dhafka ah ee resin fiber reinforced resin matrix (CFRP), kuwaas oo loo qaybin karo laba nooc: thermoset ama thermoplastic iyadoo loo eegayo qaab-dhismeedka resin ee kala duwan. Qalabka isku-dhafka ah ee thermosetting badanaa wuxuu ka kooban yahay epoxy resin, oo ah isku-xidhka kiimikada kaas oo si joogto ah ugu dari kara walxaha hal jidh. Isku-dhafka Thermoplastic wuxuu ka kooban yahay resin thermoplastic oo jilicsan oo la dhalaalin karo oo dib loo farsamayn karo, laakiin tani waxay si lama huraan ah u saamayn doontaa xoogga iyo adkaanta maaddada.

Xidhmooyinka kiimikada ee ku jira vCFRP waa la isku xidhi karaa, la goyn karaa, oo dib loo xidhi karaa si loo helo "dhul dhexe" oo u dhexeeya walxaha thermoset iyo thermoplastic. Cilmi-baarayaasha mashruucu waxay aaminsan yihiin in Vitrimers ay noqon karaan beddel u ah resins-ka thermosetting oo ay ka fogaadaan ururinta isku-dhafka thermosetting ee meelaha qashinka lagu shubo. Cilmi-baarayaashu waxay aaminsan yihiin in vCFRP uu noqon doono isbeddel weyn oo ka yimaada walxaha dhaqameed una gudbo walxaha firfircoon, waxayna yeelan doonaan saameyn taxane ah marka loo eego kharashka wareegga nolosha oo dhan, isku halaynta, badbaadada, iyo dayactirka.

Waqtigan xaadirka ah, daabyada dabaysha ayaa ka mid ah meelaha isticmaalka CFRP uu aad u badan yahay, soo kabashada daabyaduna had iyo jeer waxay ahayd dhibaato ka jirta goobtan. Ka dib markii muddada adeegga la dhammeeyay, kumanaan daabyo hawlgab ah ayaa lagu tuuray qashin-qubka qaab qashin-qub ah, taasoo saameyn weyn ku yeelatay deegaanka.

Haddii vCFRP loo isticmaali karo soo saarista daabyada, waxaa dib loo warshadeyn karaa oo dib loogu isticmaali karaa kuleyl fudud. Xitaa haddii daabkii la daweeyay aan la hagaajin karin oo dib loo isticmaali karin, ugu yaraan waxaa burburin kara kulayl. Maaddada cusub waxay wareegga nolosha toosan ee isku-dhafka thermoset u beddeshaa wareeg nololeed oo wareeg ah, kaas oo noqon doona tallaabo weyn oo loo qaado horumar waara.

Haddii vCFRP loo isticmaali karo soo saarista daabyada, waxaa dib loo warshadeyn karaa oo dib loogu isticmaali karaa kuleyl fudud. Xitaa haddii daabkii la daweeyay aan la hagaajin karin oo dib loo isticmaali karin, ugu yaraan waxaa burburin kara kulayl. Maaddada cusub waxay wareegga nolosha toosan ee isku-dhafka thermoset u beddeshaa wareeg nololeed oo wareeg ah, kaas oo noqon doona tallaabo weyn oo loo qaado horumar waara.

Waqtiga boostada: Noofambar-09-2021