Shabaq FRP oo Pultruded ah

Hordhac ku saabsan Badeecadaha Shabaqa FRP

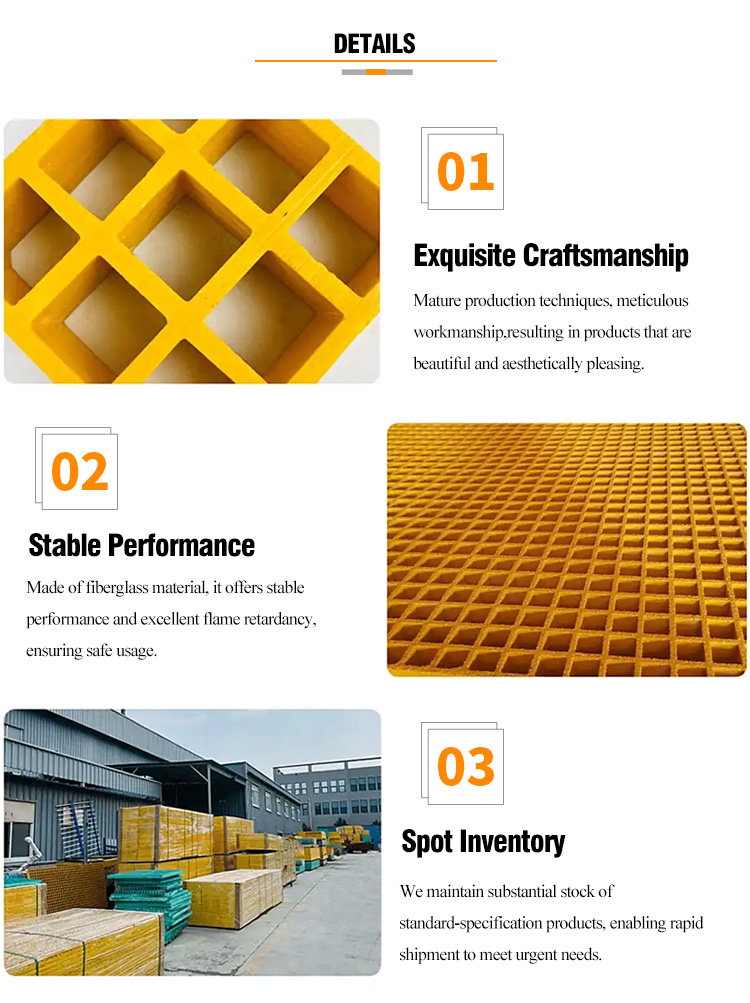

Shabaqa fiberglass-ka ee la shiiday waxaa lagu sameeyaa habka pultrusion-ka. Farsamadani waxay ku lug leedahay in si joogto ah loo soo jiido isku-darka fiilooyinka galaaska iyo resin iyada oo loo marayo caaryo kulul, iyadoo la samaynayo astaamo leh isku-dheellitirnaan qaab-dhismeed oo sare iyo cimri dherer. Habkan wax-soo-saarka ee joogtada ah wuxuu hubiyaa midnimada badeecada iyo tayada sare. Marka la barbardhigo farsamooyinka wax-soo-saarka dhaqameed, waxay u oggolaanaysaa xakamaynta saxda ah ee ku saabsan maaddada fiber-ka iyo saamiga resin-ka, taasoo hagaajinaysa sifooyinka farsamada ee badeecada ugu dambeysa.

Qaybaha culayska qaada waxay leeyihiin astaamo qaabaysan oo qaabaysan oo qaabaysan oo qaabaysan oo ay ku xiran yihiin ulo wareegsan oo gaar ah oo ah isgoysyo. Naqshaddani waxay gaarsiisaa dheelitirnaan ugu habboon oo u dhaxaysa xoogga iyo miisaanka. Injineernimada qaab-dhismeedka, alwaaxyada I waxaa si weyn loogu aqoonsan yahay inay yihiin xubno qaab-dhismeed oo aad waxtar u leh. Joomatarigoodu wuxuu diiradda saaraa inta badan walxaha ku jira flanges-ka, isagoo keenaya iska caabin aan caadi ahayn oo ka dhan ah cadaadiska foorarsiga iyadoo la ilaalinayo miisaan yar oo is-miisaamid ah.

Faa'iidooyinka Muhiimka ah iyo Astaamaha Waxqabadka

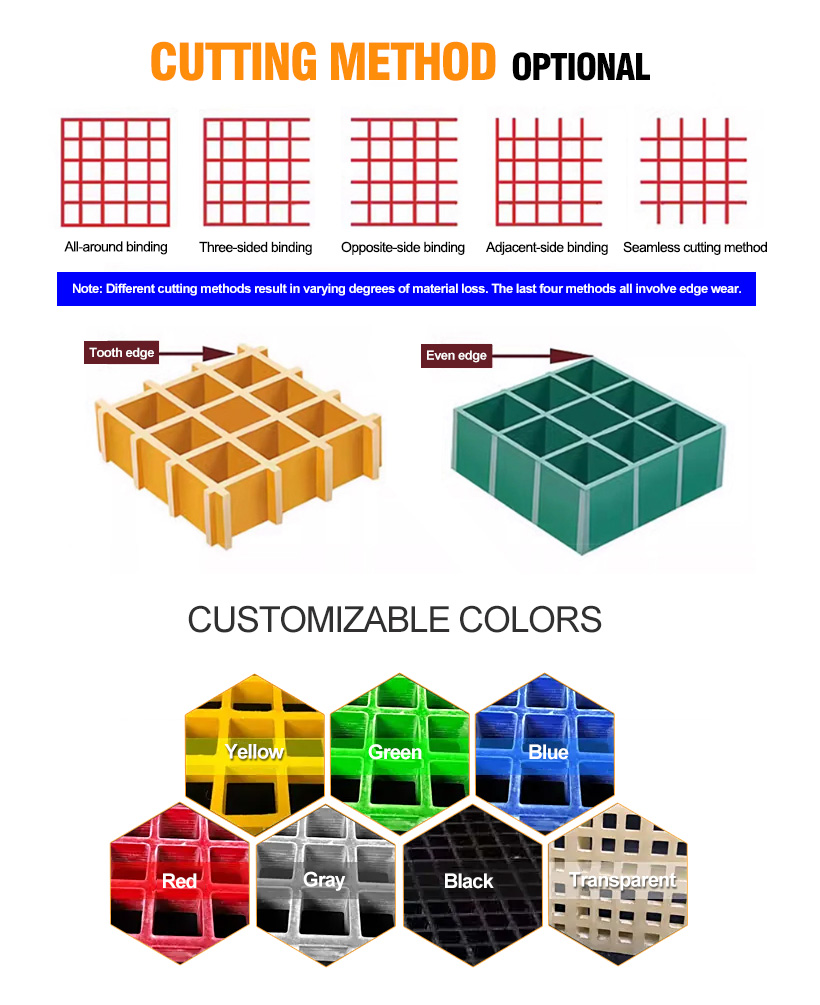

Maadaama ay tahay walxo isku dhafan oo waxqabad sare leh, shabagga fiberglass (FRP) wuxuu door muhiim ah ka ciyaaraa codsiyada warshadaha casriga ah iyo kaabayaasha dhaqaalaha. Marka la barbardhigo walxaha birta ama shubka dhaqameed, shabagga FRP wuxuu bixiyaa faa'iidooyin kala duwan sida iska caabbinta daxalka ee aan caadiga ahayn, saamiga xoogga-ilaa-miisaanka sare, sifooyinka dahaarka korontada, iyo shuruudaha dayactirka oo hooseeya. Intaa waxaa dheer, shabagga FRP waxaa lagu sameeyaa iyadoo la adeegsanayo habka pultrusion si loo sameeyo astaamaha "I" ama "T" sida xubno culeys qaada. Kuraasta ul gaar ah waxay isku xiraan isgoysyada, iyada oo loo marayo farsamooyinka gaarka ah ee isu imaatinka, waxaa la sameeyaa guddi daloolsan. Dusha sare ee shabagga pultruded wuxuu leeyahay godad si looga hortago simbiriirixan ama waxaa lagu dahaadhay dhammaystir matte ah oo ka hortagga simbiriirixan. Iyada oo ku xidhan shuruudaha codsiga ee wax ku oolka ah, saxannada qaabaysan ee dheemanka ama saxannada dahaarka leh ee ciidda lagu dahaadhay ayaa lagu xidhi karaa shabagga si loo abuuro naqshad unug xiran. Astaamahan iyo naqshadahani waxay ka dhigayaan beddel ku habboon warshadaha kiimikada, xarumaha daaweynta biyaha wasakhda ah, warshadaha korontada, goobaha badda, iyo meelaha kale ee u baahan iska caabbinta deegaannada daxalka ama shuruudaha socodka adag.

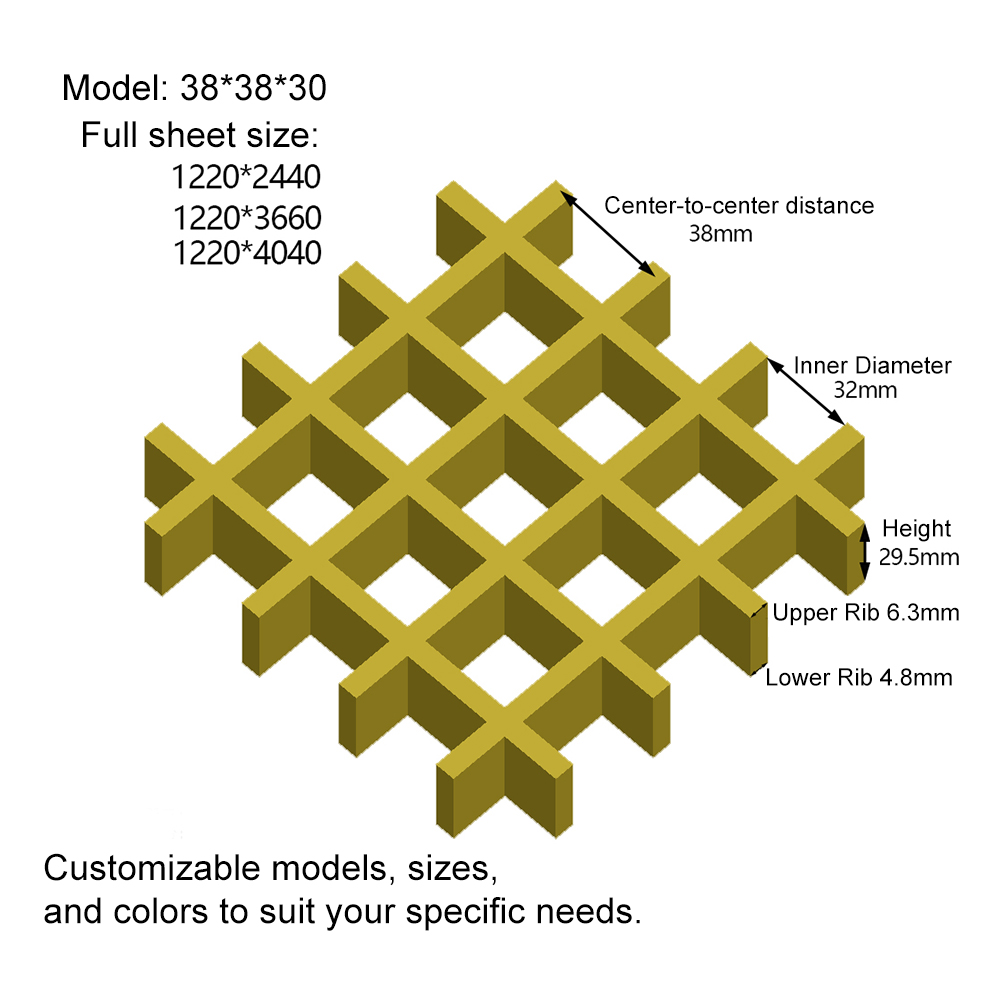

Qaabka Unugga Shabaqa iyoTilmaamaha Farsamada

1. Shabaqyada Fiberglass-ka ee Pultruded - Tilmaamaha Moodeelka Taxanaha T

2. Tilmaamaha Moodeelka Taxanaha I ee Shabaqa FRP ee Pultruded

| Moodel | Dhererka A (mm) | Ballaca Cidhifka Sare B (mm) | Ballaca Furitaanka C (mm) | Aagga Furan % | Miisaanka Aragtida (kg/m²) |

| T1810 | 25 | 41 | 10 | 18 | 13.2 |

| T3510 | 25 | 41 | 22 | 35 | 11.2 |

| T3320 | 50 | 25 | 13 | 33 | 18.5 |

| T5020 | 50 | 25 | 25 | 50 | 15.5 |

| I4010 | 25 | 15 | 10 | 40 | 17.7 |

| I4015 | 38 | 15 | 10 | 40 | 22 |

| I5010 | 25 | 15 | 15 | 50 | 14.2 |

| I5015 | 38 | 15 | 15 | 50 | 19 |

| I6010 | 25 | 15 | 23 | 60 | 11.3 |

| I6015 | 38 | 15 | 23 | 60 | 16 |

| Muddada | Moodel | 250 | 500 | 1000 | 2000 | 3000 | 4000 | 5000 | 10000 | 15000 |

| 610 | T1810 | 0.14 | 0.79 | 1.57 | 3.15 | 4.72 | 6.28 | 7.85 | - | - |

| I4010 | 0.20 | 0.43 | 0.84 | 1.68 | 2.50 | 3.40 | 4.22 | 7.90 | 12.60 | |

| I5015 | 0.08 | 0.18 | 0.40 | 0.75 | 1.20 | 1.50 | 1.85 | 3.71 | 5.56 | |

| I6015 | 0.13 | 0.23 | 0.48 | 0.71 | 1.40 | 1.90 | 2.31 | 4.65 | 6.96 | |

| T3320 | 0.05 | 0.10 | 0.20 | 0.41 | 0.61 | 0.81 | 1.05 | 2.03 | 3.05 | |

| T5020 | 0.08 | 0.15 | 0.28 | 0.53 | 0.82 | 1.10 | 1.38 | 2.72 | 4.10 | |

| 910 | T1810 | 1.83 | 3.68 | 7.32 | 14.63 | - | - | - | - | - |

| I4010 | 0.96 | 1.93 | 3.90 | 7.78 | 11.70 | - | - | - | - | |

| I5015 | 0.43 | 0.90 | 1.78 | 3.56 | 5.30 | 7.10 | 8.86 | - | - | |

| I6015 | 0.56 | 1.12 | 2.25 | 4.42 | 6.60 | 8.89 | 11.20 | - | - | |

| T3320 | 0.25 | 0.51 | 1.02 | 2.03 | 3.05 | 4.10 | 4.95 | 9.92 | - | |

| T5020 | 0.33 | 0.66 | 1.32 | 2.65 | 3.96 | 5.28 | 6.60 | - | - | |

| 1220 | T1810 | 5.46 | 10.92 | - | - | - | - | - | - | - |

| I4010 | 2.97 | 5.97 | 11.94 | - | - | - | - | - | - | |

| I5015 | 1.35 | 2.72 | 5.41 | 11.10 | - | - | - | - | - | |

| I6015 | 1.68 | 3.50 | 6.76 | 13.52 | - | - | - | - | - | |

| T3320 | 0.76 | 1.52 | 3.05 | 6.10 | 9.05 | - | - | - | - | |

| T5020 | 1.02 | 2.01 | 4.03 | 8.06 | - | - | - | - | - | |

| 1520 | T3320 | 1.78 | 3.56 | 7.12 | - | - | - | - | - | - |

| T5020 | 2.40 | 4.78 | 9.55 | - | - | - | - | - | - |

Goobaha Codsiga

Warshadaha Kiimikada Batroolka: Qaybtan, shabagyadu waa inay u adkeystaan daxalka ka yimaada kiimikooyin kala duwan (asiidh, alkali, dareereyaal) iyagoo buuxinaya heerarka badbaadada dabka ee adag. Shabagooyinka Vinyl Chloride Fiber (VCF) iyo Phenolic (PIN) waa xulashooyin ku habboon sababtoo ah iska caabbinta daxalka ee gaarka ah iyo dib u dhigista ololka oo sarreeya.

Tamarta Dabaysha ee Xeebaha: Buufinta milixda iyo qoyaanka badan ee deegaannada badda ayaa aad u daxal badan. Iska caabbinta daxalka ee shabagga ku salaysan vinyl-chloride (VCF) waxay u suurtagelisaa inay u adkaysato nabaad-guurka biyaha badda, iyadoo hubinaysa badbaadada qaab-dhismeedka iyo cimriga adeegga ee goobaha xeebaha.

Gaadiidka Tareenka: Xarumaha tareenada waxay u baahan yihiin agab waara, awood culays qaadis, iyo iska caabbinta dabka. Shabaqku wuxuu ku habboon yahay goobaha dayactirka iyo daboolida kanaalada biyaha, halkaas oo xooggeeda sare iyo iska caabbinta daxalka ay u adkeysan karaan isticmaalka joogtada ah iyo jawiyada adag.